Tube & Pipe Bending

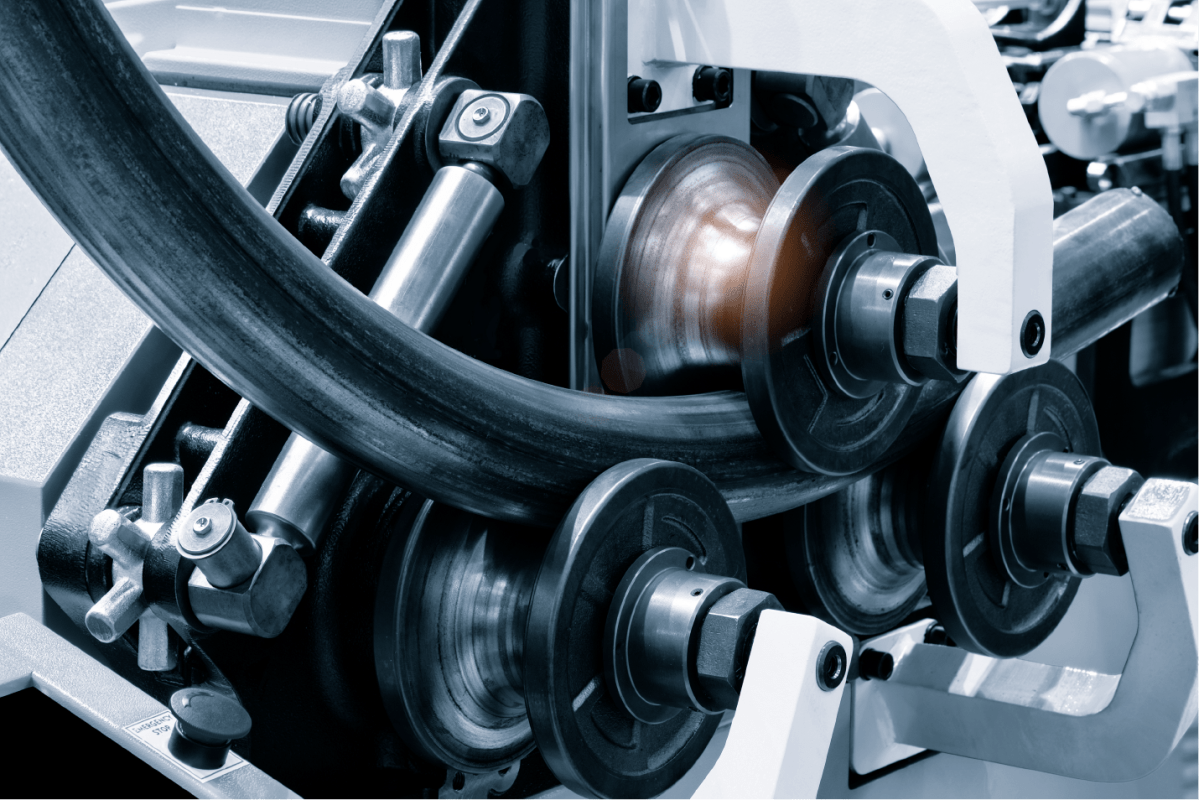

We provide precise mandrel pipe bending services to meet the demanding requirements of your project. Mandrel bending is an advanced technique that involves inserting a mandrel (a flexible support) into the pipe during the bending process, ensuring smooth, wrinkle-free bends with minimal distortion.

Key Benefits of Our Mandrel Pipe Bending Service:

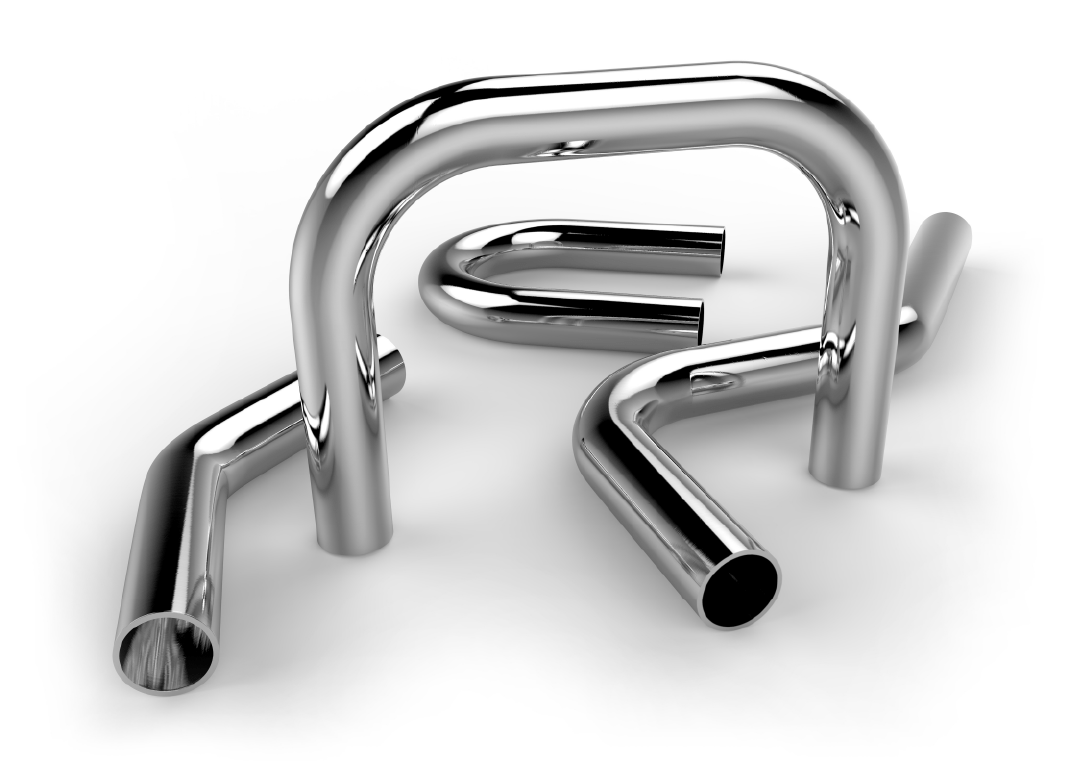

Smooth, Consistent Bends: Our mandrel bending process allows us to create tight-radius bends with superior precision, avoiding flattening or crimping even in thin-walled pipes.

High Precision: We deliver bends that meet exact specifications, ensuring that your pipes fit perfectly within your design, whether for industrial, automotive, or architectural applications.

Material Integrity: By supporting the pipe internally during bending, mandrel bending maintains the structural integrity of the pipe, making it ideal for projects where the pipe’s appearance and strength are critical.

Versatile Applications: Our mandrel bending services are suitable for a wide range of materials and pipe sizes, including stainless steel, aluminium, and steel, along with a range of other metals, making it perfect for custom and complex designs.

We can also offer other tube bending options including;

Rotary Draw Bending: Utilizes a rotating die to bend the tube around a fixed radius form. This method is ideal for producing consistent, tight-radius bends and is commonly used for complex structural components in automotive and aerospace industries.

Roll Bending: Employs three rollers to gradually bend tubes or pipes into large-radius curves. Suitable for forming structural components with gentle bends, such as those used in construction and architecture.

Compression Bending: Bends the tube by pressing it against a stationary die using a bending die, typically used for simpler, larger-radius bends in pipes and tubes.

Contact us with your requirements, and we’ll be happy to help with our range of tube bending options.