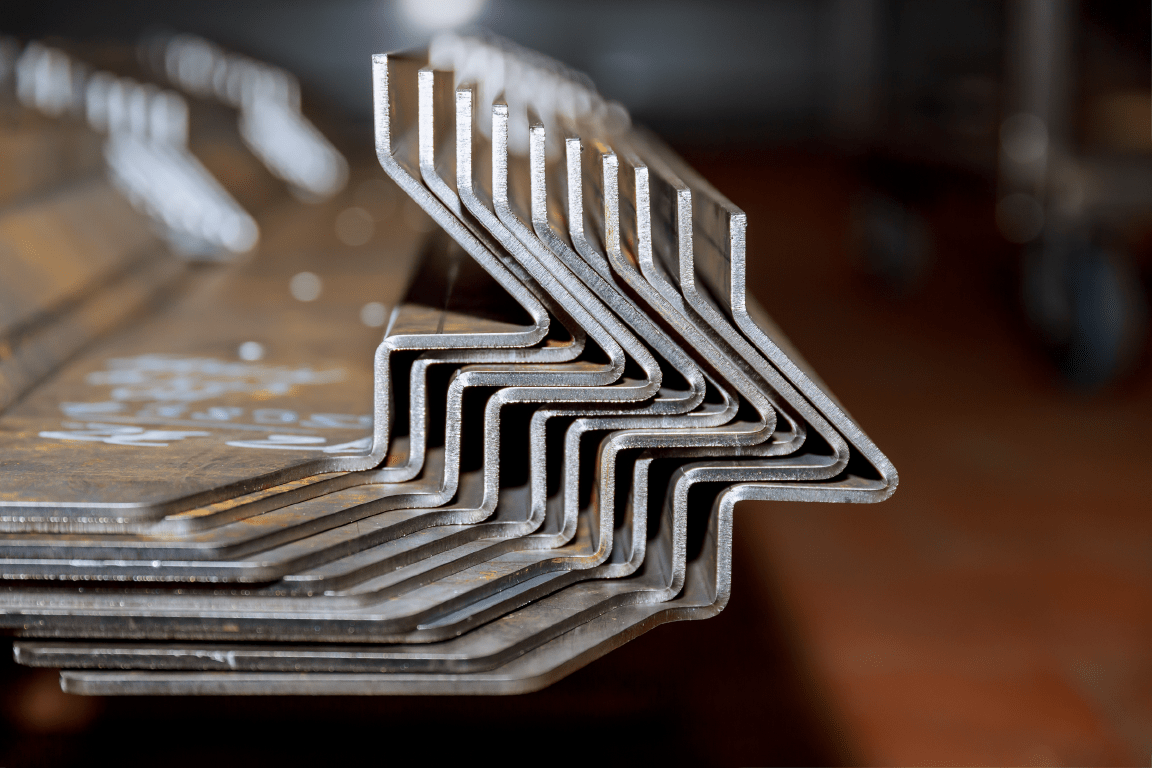

Sheet Metal Folding

At Alini Metals & Plastics, we offer sheet metal folding services are designed to deliver precise bends for a wide array of applications. We offer CNC press brake, and box pan folding machinery to ensure that every fold is executed to exact specifications. We can work with an array to designs templates and software to create your final product.

Types of Sheet Metal Folding Techniques

We offer various options for sheet metal folding, each with capabilities to produce varying folding styles, from sharp bends to rounded U-bends.

V-Bending: The most common method where the sheet is pressed into a V-shaped die. Used for creating simple bends and angles.

Air Bending: The punch does not press the sheet into the die fully, allowing for flexibility in creating different angles without changing tools.

Bottoming: The punch presses the sheet fully into the V-die, creating a more precise angle and a sharper bend.

Wiping (Edge Bending): The metal sheet is bent by a punch while a die holds it in place, ideal for creating precise, narrow folds.

U-Bending: Similar to V-bending but used to create U-shaped bends in sheet metal.

Sheet metal folding is used in a vast array of industries, with most using sheet metal folding of some type, from the folding of roof covers for humble bee hives, to intricate CNC folded sheets for food industry production. Some of the relevant industries are,

Automotive Industry: Fabrication of body panels, frames, brackets, and other structural components.

Aerospace: Manufacturing of aircraft panels, brackets, and complex structural components.

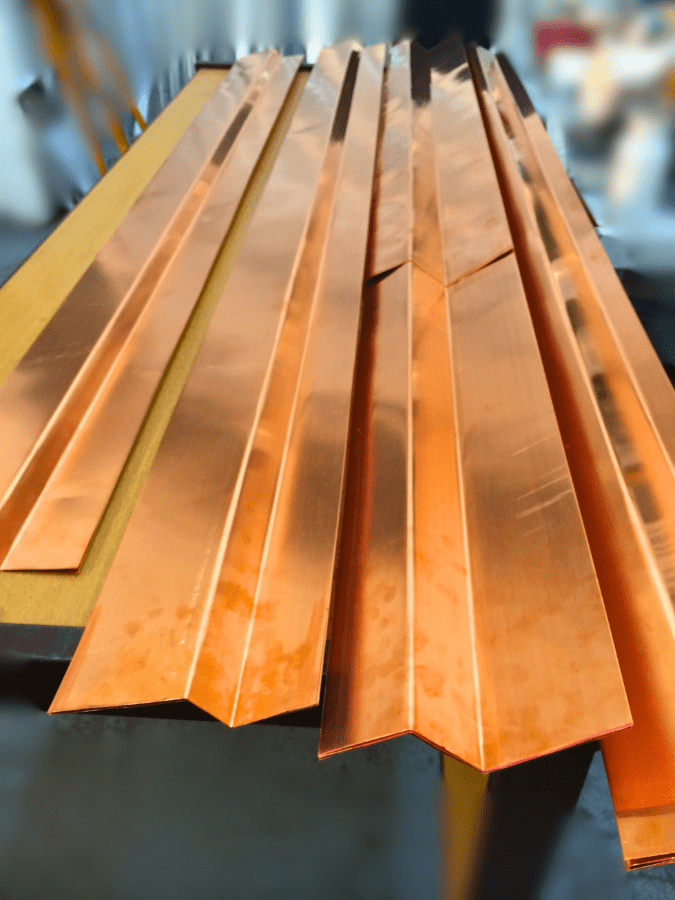

Construction: Creating roofing materials, gutters, and cladding panels.

Consumer Electronics: Producing enclosures and casings for electronic devices like computers and appliances.

HVAC Systems: Manufacturing of ducts, vents, and structural parts for heating, ventilation, and air conditioning systems.

Sheet metal folding, especially when CNC controlled offer high levels of precisions, with the ease of repeatability for high volume components. Sheet metal folding can offer;

High Precision: Folding allows for the creation of precise bends and angles, which is crucial for applications requiring tight tolerances.

Versatility: Capable of handling a variety of materials (e.g., Steel, Aluminium, Copper) and thicknesses, making it adaptable to diverse applications.

Efficiency: Offers high production speed, especially with automated machines, reducing lead times and increasing output.

Cost-Effective: Minimizes material waste by using standard-sized sheets and reducing the need for additional finishing processes.

Structural Integrity: Maintains the strength and integrity of the metal sheet, making it suitable for applications requiring durability.

Our sheet metal folding service can help reduce your in house or on-site fabrication lead times but allowing efficient supply of pre-shaped materials. Our range of folding options enables us to offer production of complex parts with high accuracy and minimal waste.

Contact us for with your project requirements and we’ll be happy to help.